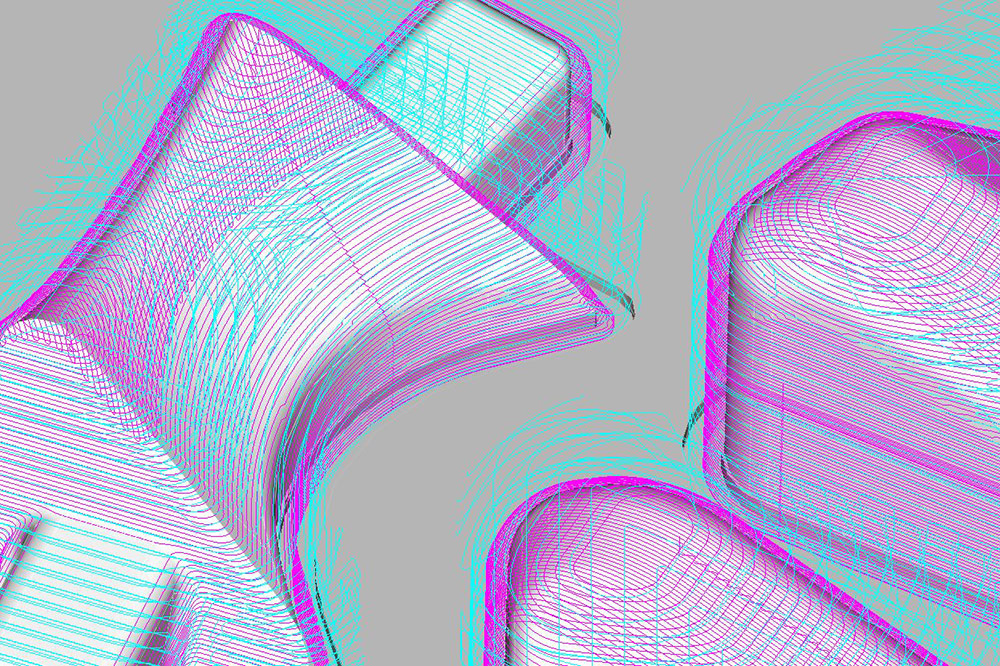

Our 5-Axis CNC machine is the most important tool in our workshop. The unique precision-engineered joinery which has become our trademark is made possible with our CNC router. The router is driven from CAD data, either provided direct from the client or designed in-house at Cambian.

CNC routing offers massive benefits in speed, accuracy, repeatability and part complexity when compared with traditional methods of wood manufacturing.